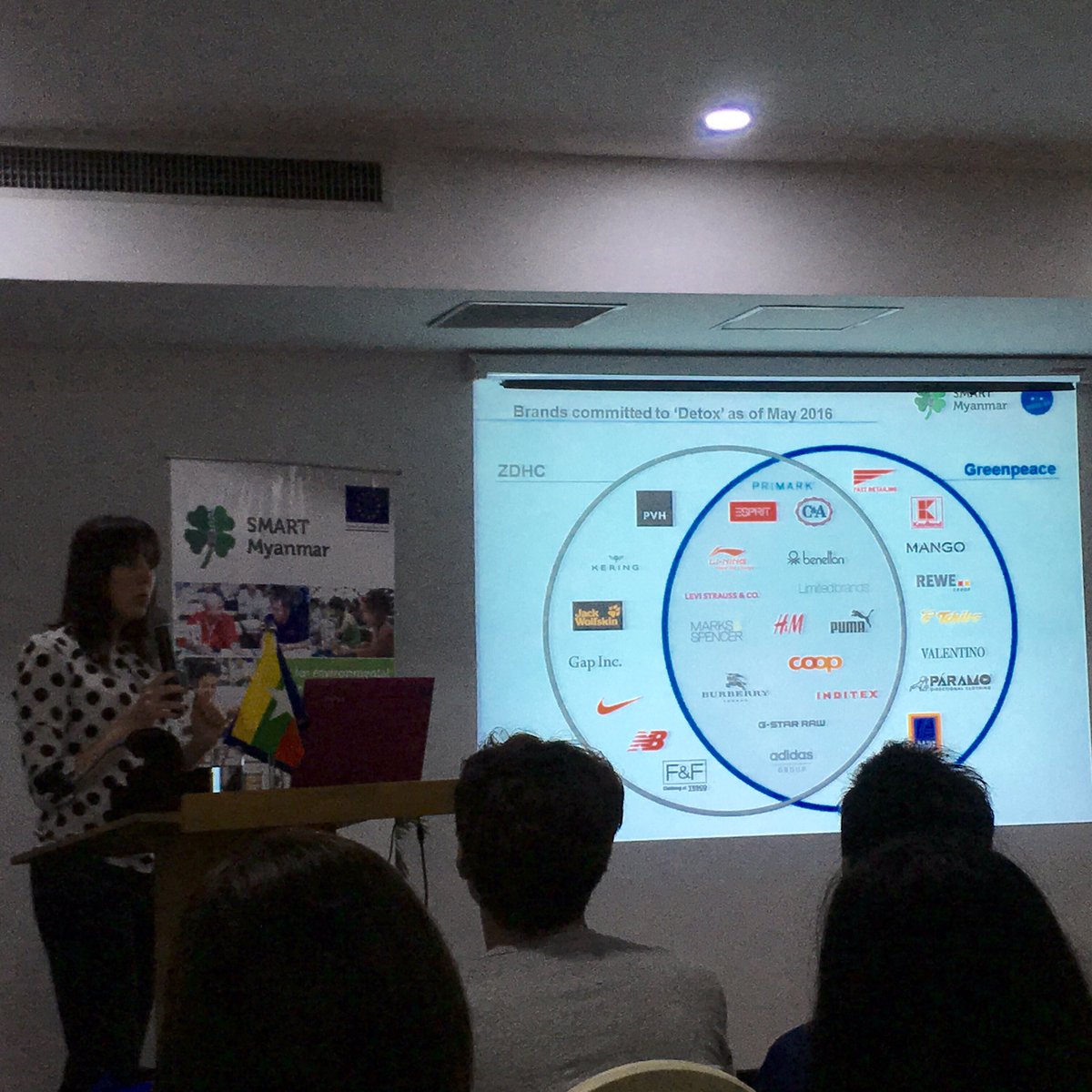

On June 17th, Dr. Christina Raab, Principal Consultant for made-by.org and one of SMART Myanmar’s implementing partners, conducted a seminar on “Environmental Labels & Sustainable Approaches” at Taw Win Garden Hotel in Yangon. This 3 hour briefing provided a strong overview on environmental sustainability topics relevant for garment production including: •Zero Discharge of Hazardous Chemicals •Higg Index of the Sustainable Apparel Coalition •The Business Environmental Performance Initiative •Oeko-tex Passport Myanmar’s garment industry is quickly expanding, and many investors have begun setting up wet processing facilities. As such, chemical usage is expanding and it is critically important that the industry adapt, via increased knowledge among factory managers and technicians, but also via an improved regulatory framework. Dr. Raab gave nearly a one hour overview on each topic, to familiarize the audience with several of the environmental standards and expectations which are increasingly being requested by European buyers.

The seminar concluded with brief comments by Julia Bakutis, Sustainability Country Manager for H&M. H&M is one of dozens of European buyers now sourcing in Myanmar, and has often commented in industry forums about their company’s expectations on environmental sustainability standards. Myanmar recently finalized “Environmental Impact Guidelines” – this action follows and builds upon previous environmental legislation, especially the 2012 Environmental Conservation Law and 2014 Environmental Conservation Rules. As such, at the same moment that buyer orders are increasing from overseas, the government is strengthening and standardizing the regulatory framework governing chemical use and waste disposal. This has good potential, but significant training and education are needed for local factory managers and technicians to help them implement these new standards. Staff from approximately 20 factories attended this event. Later this year and in 2017, SMART Myanmar will be hosting several more seminars and training modules on energy efficiency, solid waste management and the responsible handling of effluent. 10 garment factories are scheduled to receive energy audits and energy reduction consultancies in August.“Environmental Labels and Sustainable Approaches” seminar held on June 17th